SCADA hacker was conceived with the idea of providing relevant, candid, mission-critical information relating to industrial security of Supervisory Control and Data Acquisition (SCADA), Distributed Control (DCS) and other Industrial Control Systems (ICS) in a variety of public and social media forums. Since its launch in December 2011, SCADA hacker has attracted and retained over 10,000. . When reference to 60870-5 in the context of SCADA systems is made it is usually for 60870-5-101/104 titled “Companion Standard for basic telecontrol tasks. 101 protocol intended for transport of data over serial links. 104 protocol is a TCP/IP implementation of 101.

SCADA tutorial | SCADA Basics | tutorials

Siemens Scada Basics Pdf

This SCADA tutorial covers SCADA basics, applications, working of SCADA system etc. The SCADA tutorial also covers various scada system equipment categories and manufacturers.

What is SCADA?

Supervisory Control And Data Acquisition is the full form of SCADA. Remember SCADA is not specific technology but SCADA system vary based on different applications such as electrical, sewage, building, telecom, rail & roadways,energy etc. SCADA protocols depend on these applications as there are different parameters to be managed. Let us examine the same below.

SCADA Applications

SCADA has following major applications of use.

Electric Utilities- Manage Current,voltage,circuit breaker,power grid.

Water and Sewage - Monitor and control water level, water flow and water pipe pressure.

Building - Control heating,ventilation,air conditioning,visualization,lighting and building access systems.

Mass Transit - regulation of electricity, track and locate buses,trams,trains

Railways/Roadways - Control traffic signal lights

Working of SCADA System

Following basic functions are performed by SCADA in general irrespective to applications. Data Acquisition, Data Communication, Data Presentation in various formats, Data Control based on various parameters. All these functions are done by following equipment categories.

SCADA equipment basic categories

Sensors - There are analog and digital type of sensors. With digital type discrete level of monitoring is taken care. With analog type precise measurement of value is performed. There are sensors for temperature,humidity,current,motion, water applications. For data acquision sensors are attached with RTUs to take measurements.

SCADA Remote Telemetry Units(RTUs)- These units are interfaced with sensors as well as with SCADA master using communication network. They provide deliver various parameters to central station(SCADA master) to be managed by them.

SCADA Master - Composed of programmable controls, multiprotocol support and provides human interface. It takes inputs from sensors via RTUs and regulate various applications. Provides various display formats in graphs, tabular and other forms. It will have various LEDs/Alarms for various functions. It also provides email/paging based on certain conditions.

Communication medium/network - These are various interfaces to connect SCADA master with SCADA RTUs.

Scada Basics Pdf Online

SCADA System manufacturers

Following are the companies which are manufacturers of scada equipments.

• Suzlon

• ITI Limited

• ABB

• NCS

• Control Systems Inc.

• Nota Bene Technology

• Globalcom Satellite Communications

SCADA tutorial related links

For website details of SCADA equipment manufacturers for various applications, READ MORE➤➤

RF measurementsAntenna tutorialSatellite tutorial

RF Wireless Tutorials

Share this page

Translate this page

What are SCADA systems able to do?

As it is known, the SCADA systems are able to measure and monitor different parameters and variables, such as: the level of liquids, the volume of the gases, the volumetric flow rate, the mass of liquids and gases, the pressure, the temperature, the humidity, the viscosity, the position and the moving, etc.

For this, some signals must be acquired based on the appropriate sensors and transducers from different electrical and electronic devices, before to be processed and analyzed by SCADA system. These data can be used for supervision of remote processes.

For this, the data are processed and analyzed to generate reports which will be transmitted to control the processes parameters within certain limits.

The SCADA applications have two basic levels:

- The customer level, which will be performed the human-machine interaction;

- The data server level which will control the entire process.

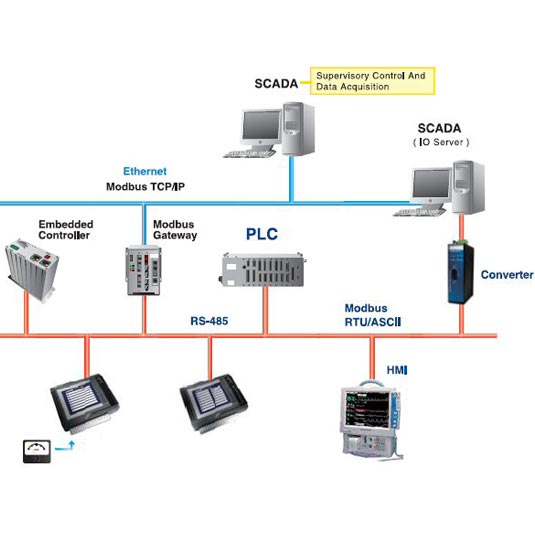

Thus, the data server sends these data to the customer level via remote equipment such as PLCs (connected to the database server either directly or via a communications network, using various communication protocols).

The SCADA systems may be relatively simple or very complex, depending of the dimension and complexity of the process monitored. These systems operate in real-time using a database system named Real Time Data Base (RTDB), which can be found on one of servers.

Software Architectures

The SCADA applications are implemented based on the software architecture (Figure 2 below). SCADA software architecture has at least two components:

- The SCADA server application;

- The SCADA client application;

SCADA server and SCADA client

The SCADA server application is multi-tasking being responsible for storing the SCADA client applications in a database. The SCADA client application receives data via serial port using RS232 and MODBUS RTU protocols.

In many cases the SCADA applications shall be addressed to and remove the users who have not an Internet connection. In this case it is necessary a new software component on a Web server. A Web server is used for generating dynamic Web pages, which are supplied to customers decrease.

Scada Tutorial Pdf Free Download

But, the Web SCADA clients do not receive the same level of graphical user interfaces and have the same HMI features as the regular SCADA clients. The regular SCADA clients are accustomed to running specific applications as opposed to The Web SCADA clients who view the Web pages provided by Web SCADA server.

Scada Tutorial Pdf

In order to reduce as much difference between the regular SCADA clients and Web SCADA clients some drives, services and virtual instruments are implemented in HMI. Visualization software used for monitoring and control of industrial process is called “software” HMI or “SCADA software”.

HMI/SCADA appeared as a terminal dedicated for users from the system implemented with PLC units. A PLC is programmed to automatically control a process. Because the PLC units are distributed in a large system, the data from PLC are stored and then transmitted. HMI/SCADA has the role to gather and combine the data from the PLC using a specific protocol.

HMI software can be connected to a database in order:to fulfill the charts and diagrams in real time:

- To analyze the PLC data;

- To treat the planned maintenance;

- To drill the schemes for a particular sensor or machine;

- To apply the troubleshooting methods of the system.

The basic SCADA protocol is MODBUS, which is designed to send data to the master station even when the master interrogates the RTU station. MODBUS is based on a master-slave architecture known also as client-server architecture.

The protocol is designed to be used by Modicon in own PLCs. Now, it became a standard of communication for the industry and is currently the most widely used to connect all the industrial devices. The protocols contain extensions to operate over Transmission Control Protocol (TCP/IP).

In practice, it is suggested to avoid the security of Internet connection in order to reduce risks of cyber-attacks.

This protocol has the following features:

- It is an open protocol with available documentation;

- It can be quickly implemented (in few days, not months);

- It works with bits and bytes, so no particular requirements on implementation.

MODBUS allows the management of the network devices, which gives new features to the SCADA system related to flexibility, reliability and safety in operation at high performance.

Reference // SCADA Applications for Electric Power System by Naser Mahdavi Tabatabaei, Ali Jafari Aghbolaghi